Amandine looks at how we can form healthier consumer habits and increased recycling rates by enforcing regulations around complex materials. Plastic materials are influenced by multiple components when formed into products, such as additives, resins, or complex designs. This makes it considerably more difficult for these materials to be recycled effectively, causing greater strain on worldly efforts to reduce waste disposal into landfill. This research reviews the various challenges faced as a result, in addition to evaluating the ways in which regulations are currently aimed to tackle them. Three materials were identified: bio-based, biodegradable, compostable plastics; multilayer packaging; and polystyrene, that are known to cause greater complexity in the waste sorting industry. It is shown that the implementation of bans or restrictions on these three types of materials provides significant potential to increase rates of recycling, save energy usage, and consequently reduce emissions of GHG’s.

Bio-based, biodegradable, compostable plastics (BBCP) example: Bioplastics

The primary issue of some bioplastics is that current MRFs are not equipped to handle these materials. An example of this is showcased in the context of NIR sensors, which are unable to detect and distinguish this material, and as a result, they are not recycled. This also creates further risk of contamination as the material is sorted into in foreign waste streams, which is typically seen with the most common bioplastic – PLA, as it enters and contaminates PET and HDPE streams. Additionally, confusion towards BBCP materials amongst consumers causes many problems in household waste separation, which further disrupts the waste management process. The introduction of bioplastics as a more ‘eco-friendly’ and ‘sustainable’ alternative has also created a diversion for other materials that do support the closed-loop system of re-use. Such issues showcase that the limitations of bioplastics outweigh the benefits, and because of this it is encouraged to impose bans on these materials along with other BBCP’s.

As of yet, limited research has been conducted concerning certain bioplastics to showcase their benefit towards the environment, however it is evident that there are many gaps in their overall support towards a sustainable ecosystem. Entities such as the Green Alliance have recommended that governments impose measures to reduce the confusion of these materials in order to strengthen the recycling infrastructure. Additionally, research is also being conducted to discover ways to process PLA successfully, such as chemical depolymerisation.

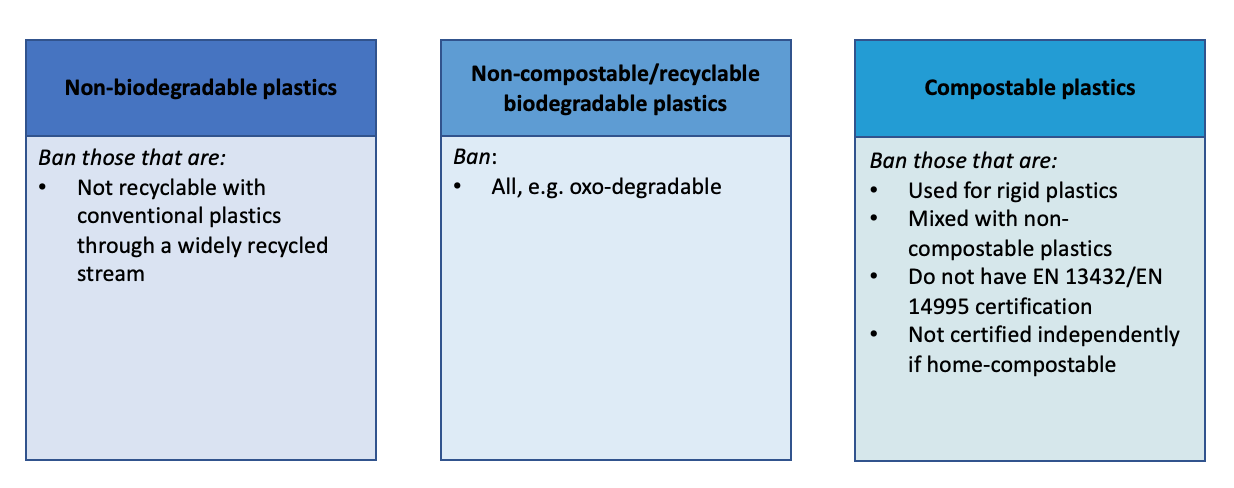

Proposed Regulations to Increase Recycling Rates: BBCP ban

Types of plastics to include in the BBCP ban

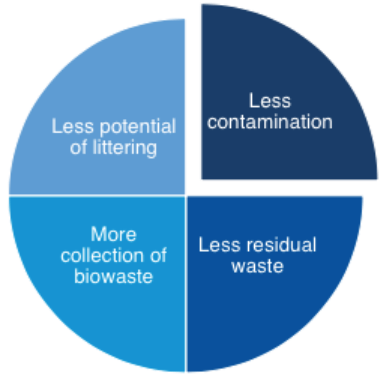

Environmental and social impacts of the BBCP ban

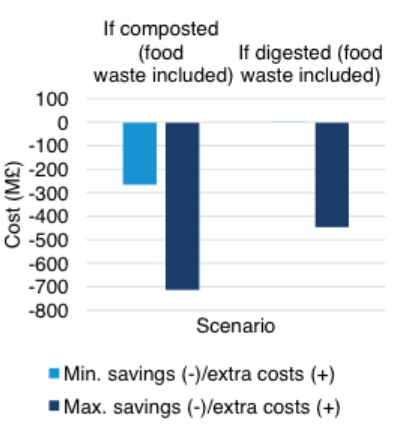

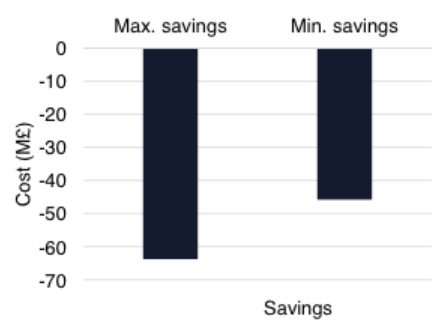

Economic savings per year in the UK due to impact of BBCP ban on disposal

The main challenges of implementing bans on BBCP materials would be the investment needed for new collection systems, in addition to the investment needed for adapted infrastructure: composting stage at anaerobic digestions plants, and more in-vessel composting plants.

Polystyrene example: (E)PS

Polystyrene is very difficult to recycle, requires further processing measures, and does not provide economic gain. The material’s lower density version, Expanded Polystyrene (EPS), is also very bulky, which provides obstacles towards its collection, transportation, and sorting activity. In addition to this, polystyrene is often contaminated by food, making it non-recyclable as a result.

At present, there is no ban on Polystyrene, however the UK is considering a ban on EPS for food and leveraging packaging. Solvent-based purification methods of the material have been created to treat the contaminated waste, but this process is currently still being tested, among alternative methods.

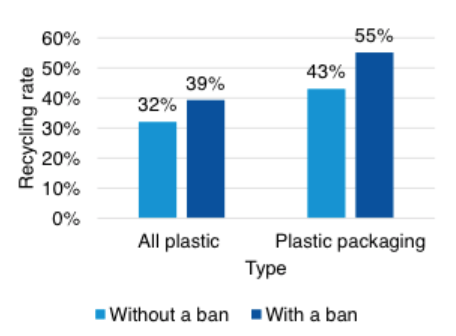

Proposed Regulations to Increase Recycling Rates: (E)PS Ban

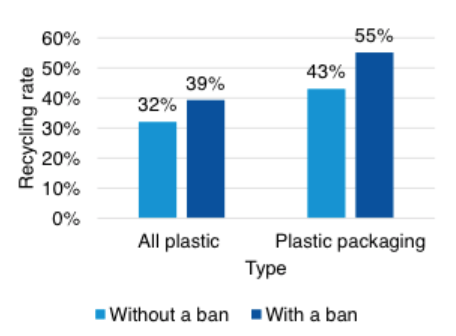

Effects of an (E)PS ban on plastic recycling rates

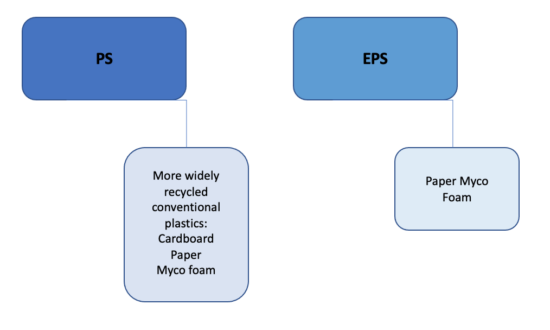

Replacements that are environmentally beneficial for PS and EPS

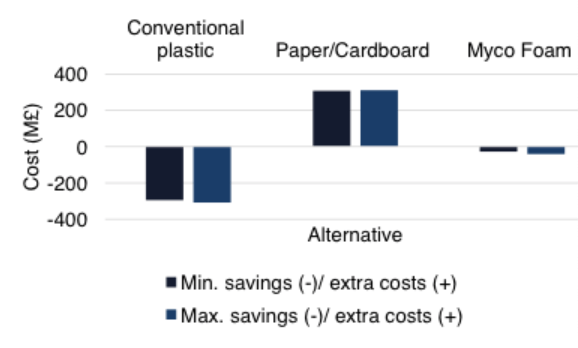

Economic impacts of an (E)PS ban per year in the UK due to better disposal of alternatives

The main challenges for implementation of this ban would be finding an adequate replacement for EPS, in addition to small businesses requiring economic support to make these necessary changes.

Multilayer designs: MLP example

MLP solutions occupy around 20% of flexible packaging used, and is often composed of PET, PP, and aluminium.

The main issue of concern is that the complex layering of these materials is very difficult to separate, and often this means that they are not recycled. Additionally, due to their complex nature, false readings are typically caused by NIR sensors, and there is therefore greater risk of contamination of homopolymer streams. The high adhesion between the complex layers of material also leads to greater difficulty in finding technological and economical viable systems that guarantee successful delamination of each material. Despite this, in the eyes of organisations that market products using MLP, the benefits of multilayer packaging often override the limitations as they grant an extended shelf life of products for consumers to benefit from. It is important for consumers to become aware of the difficulties of multi-layer materials in order to drive change.

Currently, there is no regulatory ban on multilayer packaging despite advice from entities such as Green Alliance to impose bans or set targets for their reduction. However, new technologies have been explored to either recover value from these materials, improve the design, or avoid contamination into other recyclable streams

Proposed Regulations to Increase Recycling Rates: LLP Ban

Effects of an MLP ban on plastic recycling rates

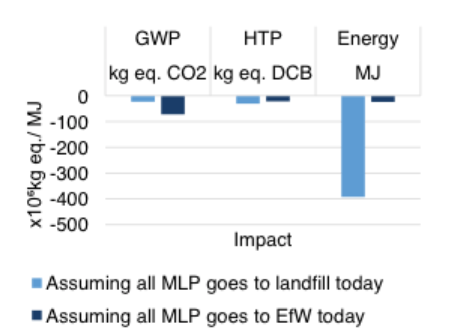

Environmental benefits of an MLP ban per year in the UK due to better disposal of recyclable replacements

Economic savings per year in the UK due to the impact of the MLP ban on disposal

The main challenges of imposing this ban include finding an adequate replacement, as well as the investment needed to revamp supply chains of organisations to facilitate these changes.

In Conclusion

Despite the proposed regulated bans, it is evident that bans alone would not be sufficient to combat further accumulation of waste. The primary challenge is to guarantee alternative, eco-friendly methods can be chosen. Whilst economic support can aid organisation to vouch for more environmentally-conscious solutions to packaging and product design, it does not necessarily provide the certainty in the use of sustainable materials.

This provides opportunity for artificial intelligence and digital innovation to be explored in order to allow accurately quantifiable data surrounding the impacts of materials and product design.